Sheet Metal Laser Cutting Machine is a specialized laser cutting tool designed specifically for high-precision cutting of metal sheets. This type of machine is extensively used in industries such as metal fabrication, electronics, automotive, and furniture manufacturing, where fast and accurate processing of metal sheets is essential. Here is a comprehensive overview, including product content, features, advantages, and common models.

Product Content

The Sheet Metal Laser Cutting Machine is designed to handle a wide variety of metal sheets, including:

- Stainless Steel

- Carbon Steel

- Aluminum

- Copper

- Brass

This machine utilizes a focused laser beam to rapidly heat, melt, and vaporize the material, resulting in smooth, precise cuts. Key components of a Sheet Metal Laser Cutting Machine include:

- Laser Source: Delivers a concentrated laser beam powerful enough for cutting through metal sheets of varying thickness.

- Cutting Bed: Provides a stable surface for holding metal sheets, with adjustable settings for different sizes.

- Cooling System: Maintains optimal temperatures to ensure machine stability and consistent cutting performance.

- Control System: Allows programming of cutting patterns, speeds, and laser power to meet specific production requirements.

Key Features

- High Precision: Delivers clean and precise edges with minimal burrs, ideal for intricate designs and applications requiring fine detail.

- Fast Cutting Speed: Capable of processing metal sheets at high speed, maximizing productivity, and reducing lead times.

- Versatile Material Handling: Suitable for various metal types and thicknesses, allowing flexibility in manufacturing processes.

- Automation Compatible: Many models can be integrated with automated systems for continuous, high-efficiency production, reducing manual handling and increasing throughput.

Advantages

- Increased Productivity: High speed and accuracy make this machine ideal for industries with high production demands, improving overall output.

- Cost Efficiency: Laser cutting reduces material wastage due to its precision, leading to cost savings on materials.

- Minimal Maintenance: Sheet metal laser cutters require minimal upkeep due to fewer moving parts, reducing downtime and maintenance costs.

- Eco-Friendly Operation: Enclosed models reduce emissions, dust, and noise, providing a safer and cleaner workspace.

- Low Thermal Impact: Minimal heat-affected zone (HAZ) reduces warping or distortion, preserving the integrity of the metal around the cutting area.

Common Models

Sheet Metal Laser Cutting Machines are available in various types, generally classified based on power, structure, and specific applications. Here are some common models:

Power-Based Models

- Low-Power Models (500W-2000W): Designed for cutting thin metal sheets like aluminum and mild steel with high precision. These are ideal for detailed work in small to medium-sized businesses.

- Medium-Power Models (3000W-6000W): Suitable for thicker sheets and higher production speeds, commonly used in larger-scale manufacturing.

- High-Power Models (7000W and above): Engineered to cut thicker sheets at high speeds, making them suitable for industries that require heavy-duty processing, such as automotive and aerospace.

Structure-Based Models

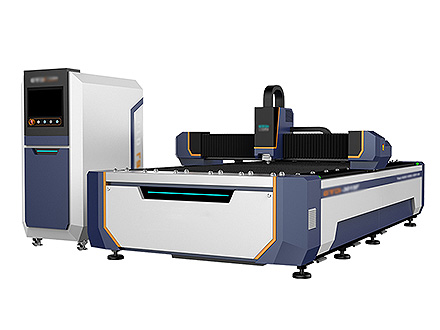

- Single-Platform Sheet Metal Laser Cutting Machine: Features a single cutting bed, suitable for medium-scale production and providing a stable platform for various sheet sizes.

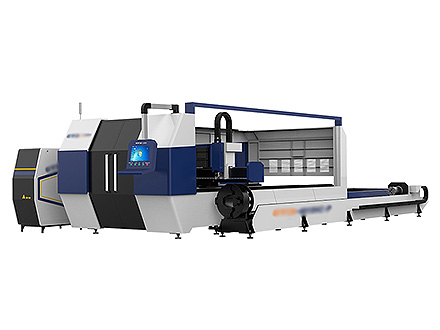

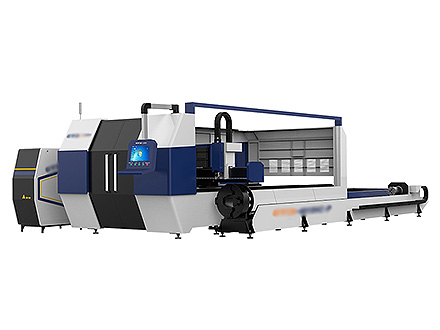

- Dual-Platform Exchange Sheet Metal Laser Cutting Machine: Equipped with two exchangeable tables, allowing one to load/unload while the other is actively cutting. This model enhances production efficiency by reducing idle time.

- Fully Enclosed Sheet Metal Laser Cutting Machine: Offers an enclosed environment for added safety and reduced emissions, ideal for workshops with strict safety standards.

- Large-Format Sheet Metal Laser Cutting Machine: Built to handle large metal sheets, commonly used in industries requiring extensive sheet processing, such as construction and shipbuilding.

Application-Based Models

- Precision Sheet Metal Laser Cutting Machine: Optimized for extremely fine cuts, ideal for electronics, jewelry, and other industries requiring high-detail work.

- High-Speed Sheet Metal Laser Cutting Machine: Designed for environments with high production demands, maximizing throughput with optimized cutting speeds.

- Automated Sheet Metal Laser Cutting Machine: Integrated with automatic loading and unloading systems, enabling continuous, unattended operation, perfect for large manufacturing facilities.