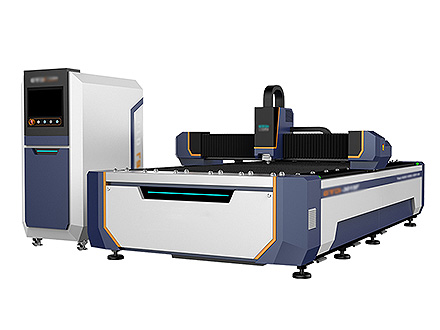

Large Format Machines are advanced cutting and processing systems designed to handle oversized materials, such as large metal sheets, heavy plates, and expansive surfaces. These machines are critical in industries that demand large-scale production, including aerospace, automotive, shipbuilding, and construction. Here’s a detailed overview of Large Format Machines, highlighting product content, features, advantages, and common types.

Product Content

Large Format Machines are engineered for extensive and high-precision work on large materials, typically handling:

- Steel Plates

- Aluminum Sheets

- Titanium and Specialty Alloys

- Composite Materials for Industrial Applications

The machines are equipped with powerful laser or plasma sources, robust frames, and expansive cutting tables to process large materials with precision. Key components include:

- High-Power Laser or Plasma Source: Delivers the necessary energy to cut or shape thick, large materials efficiently.

- Expansive Worktable: Provides a stable platform for processing large sheets and plates, with dimensions that can be customized to fit specific industry needs.

- Cooling and Ventilation System: Maintains consistent machine temperatures during extended operations, ensuring precision and stability.

- Automated Control and Programming: Allows precise control of the cutting path, speed, and power, essential for detailed and accurate processing over large surfaces.

Key Features

- Extra-Large Cutting Area: Accommodates oversized materials in a single setup, reducing the need for repositioning and increasing workflow efficiency.

- High Precision and Power: Maintains accuracy across large surfaces, making it suitable for industries with stringent quality requirements.

- Versatile Material Handling: Capable of processing a wide range of metals and composites, allowing flexibility across multiple industrial applications.

- Integrated Automation Options: Many large format machines support automated loading/unloading systems, which minimize manual handling and improve production speed.

Advantages

- Enhanced Production Capacity: Large format machines enable the processing of big materials in one setup, reducing turnaround time and improving throughput.

- Material Cost Savings: Precision cutting across large areas minimizes waste, saving material costs over extended production cycles.

- Low Maintenance Design: Built for industrial use, these machines require minimal upkeep, supporting high operational efficiency.

- Environmental and Safety Standards: Fully enclosed models reduce dust, emissions, and noise, providing a safer work environment, especially important in heavy manufacturing.

- Adaptability: Suitable for both thin and thick materials, allowing versatility in production from lightweight sheets to dense, thick plates.

Common Types of Large Format Machines

Large format machines are categorized based on power, structure, and application needs. Here are some common types:

Power-Based Types

- Medium-Power Large Format Machines (4000W-6000W): Effective for large but relatively thin materials, providing high precision for industries like automotive and electronics.

- High-Power Large Format Machines (7000W-10,000W): Capable of cutting thicker materials with speed and precision, ideal for applications in heavy-duty production.

- Ultra-High Power Machines (10,000W and above): Designed for extremely dense materials and thick plates, used in shipbuilding, construction, and aerospace for high-strength applications.

Structure-Based Types

- Fixed Table Large Format Machine: Features a stationary, expansive cutting bed, suitable for continuous production of large materials with stable support.

- Dual-Platform Large Format Machine: Equipped with two exchangeable tables for loading/unloading on one while the other processes, maximizing productivity.

- Fully Enclosed Large Format Machine: Offers a contained environment for safe operation, reducing emissions and ensuring safety in large-scale production.

Application-Based Types

- Sheet Metal Large Format Machine: Specifically designed for large metal sheets, commonly used in automotive and construction industries.

- Heavy Plate Large Format Machine: Optimized for thick, heavy plates in high-strength applications, such as shipbuilding and industrial machinery.

- Automated Large Format Machine: Integrates automatic loading/unloading and advanced control systems for high-volume production, suitable for large manufacturing facilities.