Fiber Laser Cutting Machine

Fiber laser cutting machines utilize a fiber laser as the cutting source, providing high precision and efficiency and widely applied in industries such as metal processing, automotive manufacturing, and aerospace. Below is a detailed overview, including product content, features, advantages, and common models.

Product Overview

The fiber laser cutting machine is designed for metal cutting and is suitable for materials such as stainless steel, carbon steel, aluminum alloys, and copper. Fiber laser technology focuses the laser beam on a tiny area, heating the material rapidly to its melting or vaporization point for cutting. These machines typically include automated control systems and cooling mechanisms to ensure high precision and continuous operational capabilities.

Features

- High Precision Cutting: The fiber laser beam is highly focused with a minimal heat-affected zone, producing smooth and clean cutting edges suitable for high-precision parts.

- Fast Cutting Speed: Fiber lasers have high energy density and efficient photoelectric conversion, enabling faster cutting speeds, which greatly boosts production efficiency.

- Strong Stability: Fiber lasers are known for excellent stability and consistent cutting quality, allowing prolonged continuous operation.

- Low Maintenance Cost: Fiber laser technology has a straightforward structure with low maintenance requirements and long service life.

Advantages

- High Efficiency: With over 30% photoelectric conversion efficiency, fiber lasers consume less power, making them ideal for large-scale industrial production.

- Wide Application Range: Suitable for cutting various metals with thicknesses ranging from a few millimeters to several centimeters.

- Flexible Operation: Adjustable cutting speed and power allow versatile applications across different materials, thicknesses, and cutting needs.

- High Degree of Automation: Many fiber laser cutting machines come with intelligent control systems, enabling automatic loading and optimized cutting paths, enhancing processing efficiency.

Common Models

Fiber laser cutting machines come in various models, typically categorized by power, worktable structure, and purpose. Below are some common model types:

Power-Based Models

- Low-to-Medium Power Models (1000W-3000W): Suitable for thin metal sheets such as stainless steel and carbon steel, focusing on precision cutting.

- Medium-to-High Power Models (4000W-6000W): Suitable for fast cutting across various metals, ideal for large-scale production.

- Ultra-High Power Models (10000W and above): Suitable for thicker materials, like steel plates over 10mm in thickness, often used in heavy industry and large machinery production.

Structure-Based Models

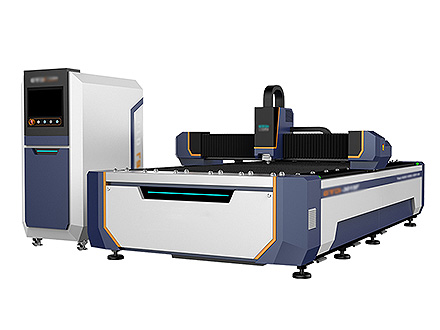

- Single Platform Fiber Laser Cutting Machine: Simple structure, ideal for small to medium-sized businesses.

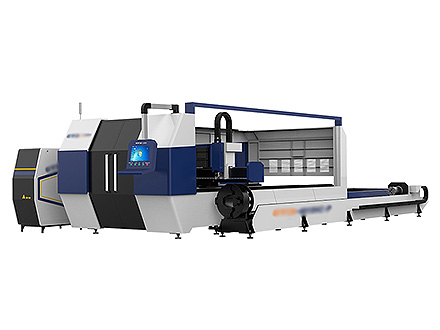

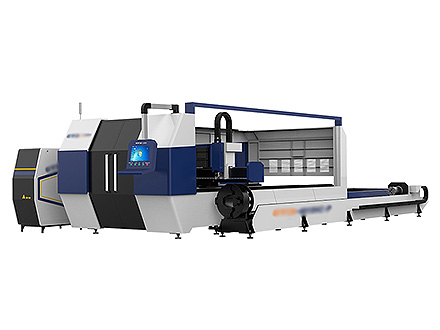

- Dual Exchange Table Fiber Laser Cutting Machine (Switch Table Laser Cutting Machine): Dual-platform automatic exchange for continuous operation, increasing production efficiency.

- Fully Enclosed Fiber Laser Cutting Machine (Fully Surrounded Laser Cutting Machine): Fully enclosed design for added safety, suitable for environments with high processing demands.

- Large Format Fiber Laser Cutting Machine (Large Format Laser Cutting Machine): Designed for large metal sheets, primarily used in aerospace and shipbuilding sectors.

Purpose-Based Models

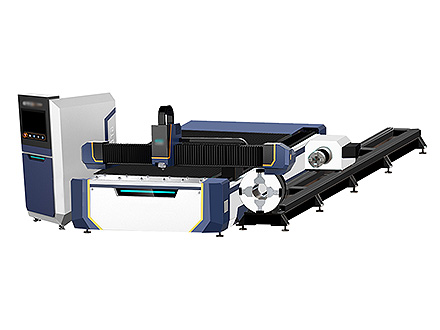

- Sheet Metal Fiber Laser Cutting Machine: Specially designed for metal sheet cutting.

- Tube Fiber Laser Cutting Machine: Specifically for metal tube cutting.

- Plate and Tube Integrated Fiber Laser Cutting Machine: Combines sheet and tube cutting capabilities, enhancing equipment flexibility.