The Fiber Laser Cutting Machine is a cutting-edge device designed to precisely cut various types of metals, such as stainless steel, carbon steel, aluminum alloys, and copper. This machine uses a focused fiber laser beam to generate high energy at a small focal point, allowing for rapid heating of the metal until it melts or vaporizes, thereby enabling precise and efficient cutting. It is widely applied in industries like metal processing, automotive manufacturing, aerospace, and other sectors that demand high precision and productivity.

Product Content

A fiber laser cutting machine primarily includes:

- Fiber Laser Source: Generates a powerful, concentrated laser beam for high-quality cuts.

- Control System: Automated controls for adjusting cutting parameters based on the material and thickness.

- Cooling System: Manages the machine’s temperature to ensure continuous operation and extend equipment life.

- Support and Safety Systems: Ensures safe handling of high-energy laser cutting.

Key Features

- Precision Cutting: The laser focuses on a narrow spot with minimal heat spread, producing smooth, clean cuts with precise detail, suitable for complex designs.

- High Cutting Speed: Fiber lasers convert energy efficiently, resulting in rapid cutting speeds and higher production capacity.

- Stability and Durability: These machines maintain consistent cutting quality over long periods due to their reliable structure and efficient fiber laser technology.

- Low Maintenance: With fewer moving parts and robust fiber optics, maintenance costs are kept low, enhancing the overall lifespan of the machine.

Advantages

- Energy Efficiency: High photoelectric conversion efficiency means reduced energy consumption, making it cost-effective for large-scale production.

- Versatile Application: Adaptable to various materials and thicknesses, from thin sheets to thick plates.

- Enhanced Automation: Many models include automated loading and cutting path optimization, increasing production efficiency.

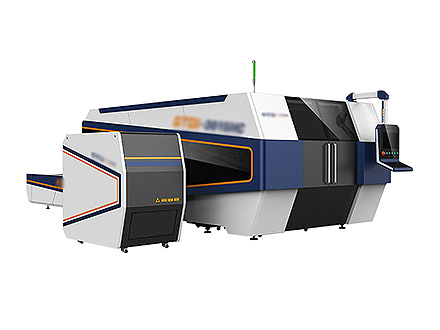

- Safety and Enclosure Options: Some models offer fully enclosed designs, enhancing safety for high-powered operations.

Common Models

Power Range Models

- Low to Medium Power (1000W-3000W): Best for thinner sheets, these models excel in precision cutting for industries requiring delicate work.

- Medium to High Power (4000W-6000W): Suited for cutting a range of metals quickly, ideal for high-volume operations.

- Ultra-High Power (10,000W and above): Capable of cutting very thick metals, commonly used in heavy-duty industrial settings.

Structure-Based Models

- Single Table Fiber Laser Machine: Compact and efficient for small to mid-sized production.

- Switch Table Fiber Laser Machine: Features a dual-platform for fast loading/unloading, allowing continuous production.

- Fully Enclosed Fiber Laser Machine: Ideal for environments where safety and minimal emissions are a priority.

- Large Format Fiber Laser Machine: Designed for larger sheets, used in fields like aerospace and shipbuilding.

Application-Based Models

- Sheet Metal Fiber Laser Machine: Specialized for cutting sheet metals with high accuracy.

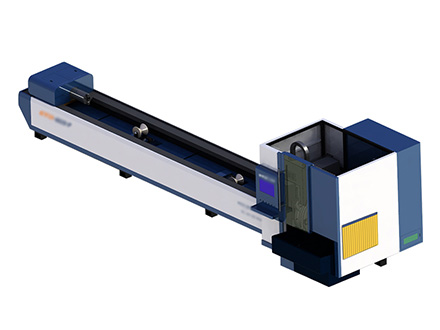

- Tube Fiber Laser Machine: Dedicated to cutting metal tubes, often used in pipeline and structural engineering.

- Plate and Tube Integrated Machine: Combines both sheet and tube cutting functions, providing flexibility for mixed-material production.