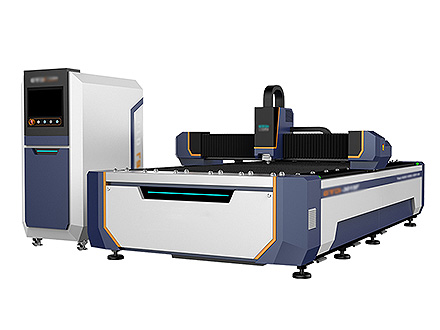

Sheet Metal Laser Cutting Machine is a specialized laser cutting tool designed specifically for cutting sheet metal with high precision and efficiency. It is widely used in industries such as metal fabrication, automotive, electronics, and furniture manufacturing, where detailed and rapid processing of sheet metal is required. Below is an in-depth overview, covering the product content, features, advantages, and common models.

Product Content

A sheet metal laser cutting machine is primarily built to handle thin and medium-thickness metal sheets, such as:

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

The machine works by focusing a laser beam onto the metal sheet, rapidly heating and melting the material to create smooth, precise cuts. Key components include:

- Laser Source: Provides the concentrated laser beam needed for precise cuts on sheet metal.

- Control System: Offers programmable controls for adjusting cutting speed, pattern, and thickness settings.

- Cooling System: Keeps the laser and equipment at optimal temperatures during operation, ensuring cutting stability.

- Sheet Handling Mechanism: Often includes automated loading/unloading for efficient handling of sheet materials.

Key Features

- High Precision Cutting: The laser beam enables precise cuts with minimal burrs or rough edges, ideal for intricate designs and patterns.

- Fast Processing Speed: The machine can cut thin and medium-thickness sheets quickly, maximizing production rates.

- Flexibility in Material Handling: Suitable for a wide variety of sheet metals, from thin aluminum to thicker stainless steel.

- Programmable and Automated: Allows integration with automated systems, providing programmable operations for batch production and reducing manual labor.

Advantages

- Enhanced Productivity: High cutting speed and precision make this machine ideal for industries with high production demands.

- Material and Cost Efficiency: Laser cutting reduces material wastage by focusing energy on the specific cutting area, leading to cost savings over time.

- Minimal Maintenance: With fewer moving parts and high stability, these machines require low maintenance and have a long operational life.

- Eco-Friendly: Many models come with enclosed designs that reduce noise, dust, and emissions, creating a safer and cleaner work environment.

- Low Thermal Impact: The minimal heat-affected zone preserves the quality of the metal around the cut, reducing warping or deformation.

Common Models

Sheet metal laser cutting machines are available in several types, classified by power levels, structural design, and specific application. Here are some common models:

Power-Based Models

- Low-Power Models (500W-2000W): Suitable for cutting thin sheet metals, such as aluminum and mild steel, focusing on high-precision and detailed work. Ideal for small workshops and businesses focused on fine cuts.

- Medium-Power Models (3000W-6000W): Capable of handling thicker sheet metals and offering faster cutting speeds, commonly used in larger production settings.

- High-Power Models (7000W and above): Designed for cutting thicker sheets with greater speed and efficiency, often used in industries with high-demand and heavy-duty sheet processing requirements.

Structure-Based Models

- Single Platform Sheet Metal Laser Cutting Machine: Features a single, large cutting bed, suitable for medium-scale production environments.

- Dual-Platform Exchange Sheet Metal Laser Cutting Machine: Equipped with two exchangeable cutting tables, enabling one table to load/unload while the other is actively cutting, greatly enhancing production efficiency.

- Fully Enclosed Sheet Metal Laser Cutting Machine: Enclosed for added safety and environmental control, preventing laser exposure, dust, and noise; ideal for workshops with strict safety requirements.

- Large Format Sheet Metal Laser Cutting Machine: Built for larger sheets, this model is frequently used in industries such as automotive and aerospace, where large components are required.

Application-Based Models

- Precision Sheet Metal Laser Cutting Machine: Focuses on delivering very fine, detailed cuts with minimal edge roughness, suited for electronics, jewelry, and other industries requiring high detail.

- High-Speed Sheet Metal Laser Cutting Machine: Designed for high-volume, rapid production environments, maximizing throughput with optimized cutting speed.

- Automated Sheet Metal Laser Cutting Machine: Integrated with automatic loading and unloading systems, allowing for continuous, unattended operation, ideal for large manufacturing facilities.