Metal Laser Cutting Machine is a versatile and powerful tool specifically designed for cutting various metal types with high precision and efficiency. This machine is widely used across industries such as metal fabrication, automotive manufacturing, aerospace, and heavy machinery, making it an essential part of modern industrial production. Below is an in-depth overview, including product content, features, advantages, and common models.

Product Content

A metal laser cutting machine is engineered to process a wide array of metals, including:

- Stainless Steel

- Carbon Steel

- Aluminum

- Copper

- Alloys

The machine operates by focusing a high-energy laser beam onto the metal, heating it to the point of melting or vaporizing, and thereby achieving precise and efficient cuts. Key components include:

- Laser Source: Provides the high-intensity laser beam necessary for cutting metals.

- Control System: Manages laser settings, movement, and cutting paths for optimal performance.

- Cooling System: Keeps the laser and machine components cool during prolonged use, maintaining stability and cutting accuracy.

- Safety and Protective Enclosures: Ensures safe operation, especially when working with high-powered lasers.

Key Features

- High Precision: Metal laser cutting machines produce highly detailed cuts with minimal material wastage, achieving clean, smooth edges suitable for intricate designs.

- High-Speed Cutting: The laser beam allows for rapid cutting of metal sheets and tubes, increasing production rates and operational efficiency.

- Material Versatility: Capable of cutting various metal types and thicknesses, making it adaptable to diverse manufacturing needs.

- Easy Automation: These machines often include software integration options, allowing for programmable operations and efficient batch processing.

Advantages

- Enhanced Productivity: High-speed and precision capabilities reduce production time, making it ideal for high-demand applications.

- Cost-Efficiency: Reduces material waste and energy consumption compared to traditional cutting methods, resulting in cost savings over time.

- Low Maintenance: With fewer moving parts, the machine requires minimal upkeep, contributing to its longevity and cost-effectiveness.

- Adaptability: Ideal for both thin and thick metal applications, from delicate sheet work to robust industrial components.

- Environmentally Friendly: Many models are designed with enclosed systems to minimize emissions, dust, and noise, promoting a cleaner working environment.

Common Models

Metal laser cutting machines come in various types based on power, structure, and intended applications. Here’s a breakdown of popular models:

Power-Based Models

- Low to Medium Power Models (1000W-3000W): These models are suited for cutting thin sheets of metal, such as aluminum and stainless steel, with high precision. Ideal for small to medium-sized businesses focused on detailed work.

- Medium to High Power Models (4000W-6000W): These machines can cut a range of metal types and are suitable for larger production volumes, often used in industries requiring versatile material processing.

- Ultra-High Power Models (10,000W and above): Designed for cutting thicker metals, such as heavy steel plates, often used in heavy industries like shipbuilding and large machinery manufacturing.

Structure-Based Models

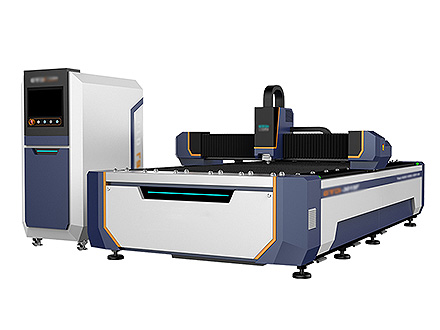

- Single Platform Metal Laser Cutting Machine: Compact and efficient, suitable for workshops and smaller manufacturing environments.

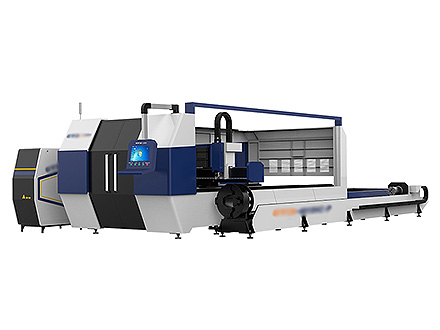

- Dual Exchange Table Metal Laser Cutting Machine: Equipped with two cutting platforms, allowing continuous production as one table loads/unloads while the other cuts. This model enhances productivity significantly.

- Fully Enclosed Metal Laser Cutting Machine: Offers added safety and environmental control, ideal for industries with strict safety standards and emissions control requirements.

- Large Format Metal Laser Cutting Machine: Designed to cut large metal sheets, commonly used in industries requiring extensive sheet processing, such as aerospace and construction.

Application-Based Models

- Sheet Metal Laser Cutting Machine: Specially optimized for flat sheet metal cutting, providing high precision for detailed sheet work.

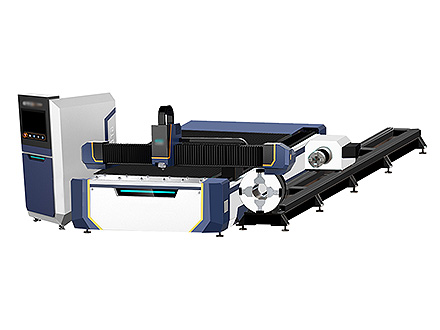

- Tube and Pipe Laser Cutting Machine: Focused on cutting metal tubes and pipes, widely used in construction, plumbing, and structural manufacturing.

- Plate and Tube Integrated Metal Laser Cutting Machine: Combines both sheet and tube cutting functions, offering versatility for mixed-material processing needs.