Tube Laser Cutting Machine is a specialized laser cutting system designed for processing metal tubes and pipes with high precision and efficiency. This type of machine is extensively used in industries such as construction, automotive manufacturing, furniture production, and structural engineering, where tubular components are integral to the final product. Below is a comprehensive overview, covering product content, features, advantages, and common models.

Product Content

The Tube Laser Cutting Machine is engineered specifically for cutting and shaping metal tubes and pipes, including:

- Round Tubes

- Square Tubes

- Rectangular Tubes

- Elliptical and Other Shaped Tubes

Materials that can be processed include stainless steel, carbon steel, aluminum, brass, and copper. The machine uses a focused laser beam to cut through these materials, delivering precise cuts without deforming the tube structure. Key components include:

- Laser Source: Provides the powerful laser beam necessary for high-precision cuts in tubular materials.

- Rotating Chuck: Holds and rotates the tube, allowing the laser to cut at various angles and around the tube’s circumference.

- Control System: Manages cutting patterns, rotation, and laser settings for optimal performance.

- Automatic Loading and Unloading System: Allows for continuous operation by automating the tube feed process.

Key Features

- 360-Degree Tube Cutting: Equipped with a rotating chuck, the machine can cut around the entire circumference of the tube, allowing for complex designs and precise angles.

- High Precision: Laser cutting provides accurate cuts with minimal thermal impact, preserving the structural integrity of the tube and ensuring smooth edges.

- Multi-Material Flexibility: Can handle various metal types and thicknesses, making it suitable for a wide range of applications.

- Automation Options: Many models come with automated loading and unloading systems, which improve efficiency and reduce manual handling.

Advantages

- Increased Efficiency: The machine’s ability to process tubes rapidly and with minimal material waste makes it ideal for high-production environments.

- Reduced Material Deformation: With minimal heat-affected zones, the laser cutting process reduces the risk of warping or damaging the tube’s structure, maintaining high quality in finished parts.

- Design Flexibility: Capable of creating intricate designs, perforations, and notches on tubes, enabling complex structural applications.

- Low Maintenance Costs: Fiber laser technology has a longer lifespan and requires minimal upkeep, reducing operational costs over time.

- Environmentally Friendly: Enclosed designs reduce noise and emissions, creating a safer and cleaner workspace.

Common Models

Tube laser cutting machines are categorized based on power levels, structure, and specific applications. Here’s a look at the most common models:

Power-Based Models

- Low to Medium Power Models (1000W-3000W): Suitable for thin-walled tubes and materials such as aluminum and mild steel, ideal for applications requiring precision and detail in light-duty tubing.

- Medium to High Power Models (4000W-6000W): These models can handle thicker tubes and provide faster cutting speeds, making them suitable for moderate to heavy-duty applications.

- Ultra-High Power Models (10,000W and above): Designed for cutting thicker tubes and heavy metals, these models are used in industries requiring robust tube cutting capabilities, such as construction and heavy machinery manufacturing.

Structure-Based Models

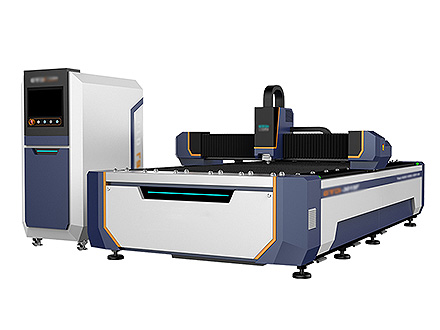

- Single Chuck Tube Laser Cutting Machine: Equipped with a single chuck that holds one end of the tube, suitable for shorter tubes and smaller operations.

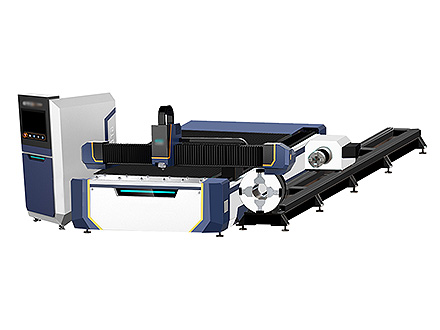

- Dual-Chuck Tube Laser Cutting Machine: Features two chucks that hold both ends of the tube, providing stability during cutting and allowing for longer tube processing. This model is ideal for large-scale production.

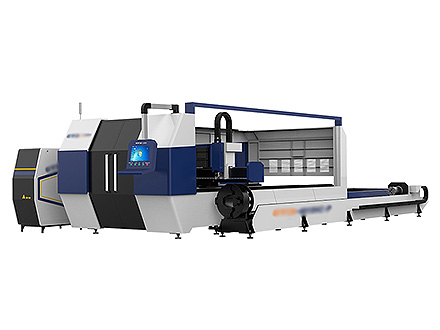

- Fully Enclosed Tube Laser Cutting Machine: Provides an enclosed cutting environment, enhancing safety and reducing dust and emissions, often used in workshops with high safety and environmental standards.

Application-Based Models

- Round and Square Tube Laser Cutting Machine: Optimized specifically for round and square tubes, commonly used in furniture manufacturing and structural applications.

- Multi-Shape Tube Laser Cutting Machine: Capable of handling tubes with complex shapes (e.g., elliptical, rectangular), making it versatile for a variety of industries.

- Automated Tube Laser Cutting Machine: Integrated with automatic loading and unloading systems, ideal for high-production environments requiring continuous, unattended operation.