Steel Cutting Machine is a powerful and specialized laser cutting system designed for processing various types of steel with high precision and efficiency. This machine is commonly used in industries like heavy machinery, construction, automotive, and shipbuilding, where steel components require accurate and robust cutting capabilities. Here’s a detailed breakdown, covering the product content, features, advantages, and common models.

Product Content

The Steel Cutting Machine is built to handle different types of steel, including:

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Tool Steel

These machines use a high-powered laser to cut through various thicknesses of steel, offering clean, precise edges and reducing the need for secondary processing. Essential components include:

- Laser Source: Provides the powerful laser beam required to cut through steel efficiently, even at high thicknesses.

- Cutting Table: Offers a large, stable surface to hold steel plates and sheets, accommodating various sizes for versatile applications.

- Cooling System: Keeps the laser and cutting area cool, ensuring stability during high-power operations.

- Control System: Manages cutting parameters such as speed, power, and pattern to achieve optimal cutting performance.

Key Features

- High Cutting Power: Capable of cutting thick and dense steel materials, including stainless steel plates and heavy-duty carbon steel.

- Precision Cutting: Produces smooth, accurate edges that minimize post-processing, ideal for parts requiring detailed work.

- Flexible Material Handling: Can cut a wide range of steel types and thicknesses, making it adaptable to various industrial needs.

- Automated Control Options: Many models are equipped with programmable systems, allowing for automated, high-efficiency operations with minimal manual handling.

Advantages

- Enhanced Productivity: With high power and rapid cutting speed, these machines significantly increase production efficiency, especially in high-demand environments.

- Material Efficiency: Precision cutting reduces waste, saving material and reducing costs over time.

- Low Maintenance: Steel cutting machines with fiber lasers require minimal maintenance, contributing to long operational life and lower operating costs.

- Consistency and Reliability: The machine’s stability ensures consistent performance, maintaining quality over long production runs.

- Environmental Safety: Many models include enclosed cutting options that reduce emissions, noise, and debris, providing a cleaner workspace.

Common Models

Steel cutting machines are available in various types, categorized by power level, structural design, and intended applications. Here’s a look at the most common models:

Power-Based Models

- Low to Medium Power Models (1000W-3000W): Suitable for thin to medium-thickness steel sheets, commonly used in applications requiring high precision with lighter-duty steel.

- Medium to High Power Models (4000W-6000W): These models can handle thicker steel plates and offer faster cutting speeds, suitable for industries requiring versatile material processing.

- Ultra-High Power Models (10,000W and above): Designed for extremely thick steel plates, often used in industries like shipbuilding and heavy equipment manufacturing.

Structure-Based Models

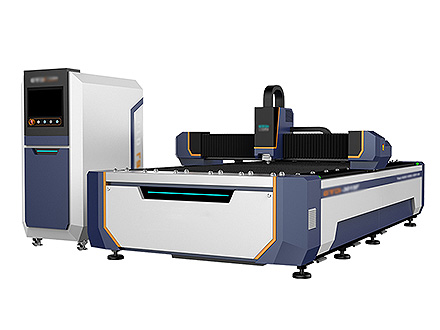

- Single Platform Steel Cutting Machine: Features a single, large cutting bed for medium-scale production environments, offering a stable setup for steel sheet processing.

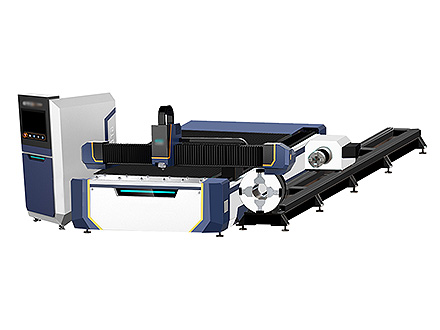

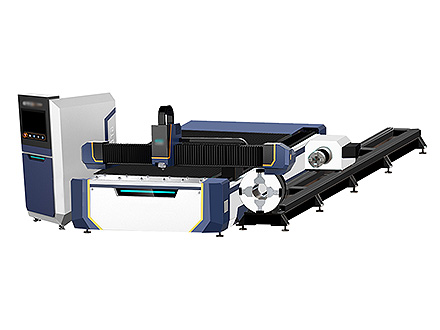

- Dual-Platform Exchange Steel Cutting Machine: Equipped with two exchangeable tables, allowing continuous production by loading/unloading on one table while the other is actively cutting. This model boosts production efficiency.

- Fully Enclosed Steel Cutting Machine: Provides an enclosed cutting environment, enhancing safety and minimizing emissions, dust, and noise. Ideal for workshops with strict safety requirements.

- Large Format Steel Cutting Machine: Designed for larger steel plates, commonly used in industries such as construction and shipbuilding, where large steel components are processed.

Application-Based Models

- Precision Steel Cutting Machine: Specialized for high-detail cuts on steel components, ideal for industries like automotive and electronics where precision is paramount.

- High-Speed Steel Cutting Machine: Optimized for rapid production, suitable for industries with high-volume steel processing demands.

- Automated Steel Cutting Machine: Integrated with automatic loading and unloading systems, enabling continuous and unattended operation, ideal for large-scale manufacturing facilities.